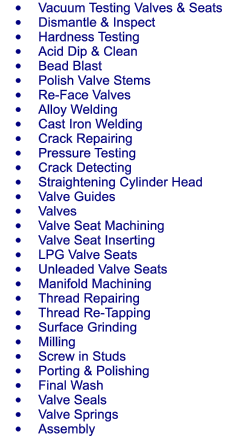

For over 39 years UMR Engines Car Repairs Slacks Creek - Brisbane has been providing business & private clients professional

cylinder head machining. Our cylinder head section is fully equipped to recondition a large range of cylinder heads with our modern

equipment and machinery which make it possible to provide a high quality job every time. We commence with carrying out a visual

inspection, hardness test (aluminium heads), check for straightness and vacuum test valves to ensure positive seating. If

reconditioning is required, we then dismantle, clean and assess the cylinder head prior contacting you with a price on

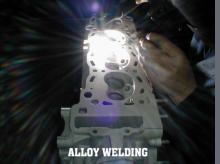

reconditioning including any parts that need replacing and any extras like welding, straightening or inserting if required. We will

require valve stem seals to reassemble your head which you can supply or we can provide a quality Valve Regrind Set (VRS) at a

competitive price.

Video of Surface Grinding Diesel Head

Cylinder Head Repairs & Car Service

Mechanic Slacks Creek - Brisbane

•

Queensland Transport Authorised to approve LA1,LA3,LB1,LD1-2,LK1,LK6 Modification’s to light vehicles

•

LPG Approved Workshop

•

RWC Licence

•

RACQ Approved Automotive Repairer

For over 39 years UMR Engines Car Repairs Slacks

Creek - Brisbane has been providing business & private

clients professional cylinder head machining. Our cylinder

head section is fully equipped to recondition a large range

of cylinder heads with our modern equipment and

machinery which make it possible to provide a high quality

job every time. We commence with carrying out a visual

inspection, hardness test (aluminium heads), check for

straightness and vacuum test valves to ensure positive

seating. If reconditioning is required, we then dismantle,

clean and assess the cylinder head prior contacting you

with a price on reconditioning including any parts that

need replacing and any extras like welding, straightening

or inserting if required. We will require valve stem seals to

reassemble your head which you can supply or we can

provide a quality Valve Regrind Set (VRS) at a competitive

price.

Video of Surface Grinding Diesel Head

Cylinder Head Repairs & Car Service

Mechanic Slacks Creek - Brisbane

7 Moss Street, Slacks Creek, Qld 4127